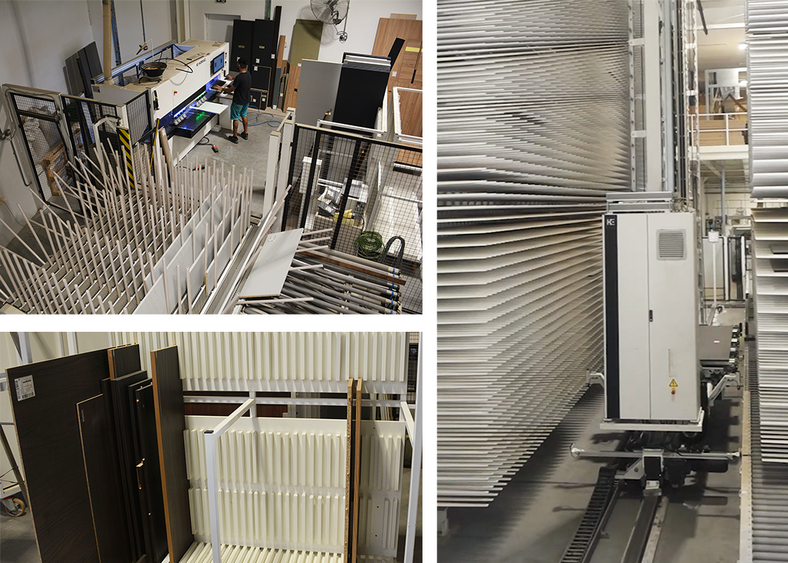

—— “Production software is more than just giving the right instructions to the

right machines at the right time. ARDIS® does exactly that, but at the same time

allows you to do various integrations and optimizations on a higher level. This

is how we get the most out of our machinery.”

Gilbert Attard, production manager SAW

Gilbert Attard, production manager SAW