—— “Each department has its own rhythm. It is my job to control these two production flows and coordinate them perfectly. Software such as ARDIS® is a crucial tool for this.”

Rolf Nooijen, Mereno

Rolf Nooijen, Mereno

Rolf Nooijen is co-owner and production manager at the family business that specializes in kitchens and bespoke interior furnishing. In addition to its own showroom Mennen Keukens, Mereno also sells through a few selected sales channels throughout the Netherlands. The projects are diverse, ranging from standard kitchens to total tailor-made designs. Mereno has been working with ARDIS® for a year now.

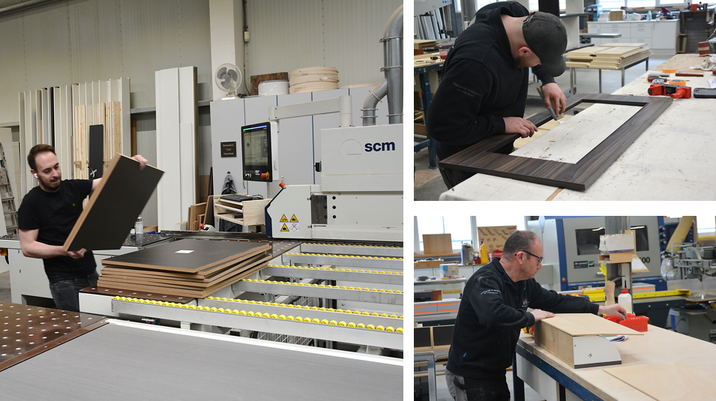

Rolf Nooijen: "The production of corpuses, fronts and other standard parts, takes place in the main building where the offices are also located. However, the bulk of our production staff is active within the traditional furniture workshop in the building across the street. That's where all the special work happens, including painting of parts."

Rolf: "We used to work with a different optimization program. The reason for the switch was the arrival of the new SCM beam saw. The choice of OPTIMIZER was prompted by a number of requirements."

"In addition, it had to be possible to generate ready-to-use machine files from the optimization results. A particular focus was the support of the FLEXCUT option on the saw. Here, separately controllable clamps allow you to further cut two strips simultaneously, each according to its own pattern, which ultimately allows you to produce faster."